Ürün Tanımı:

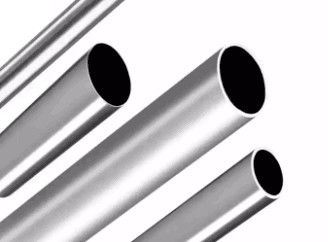

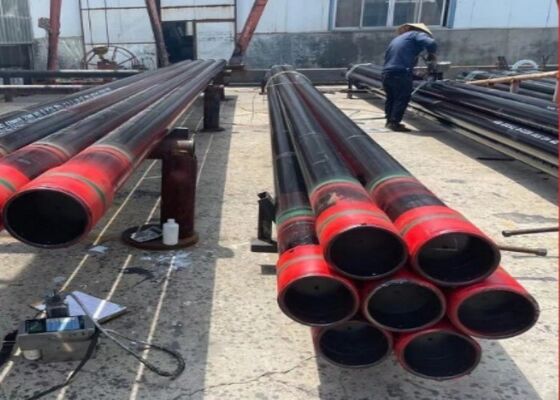

API 5CT Tubing, yüksek kaliteli bir dikişsiz çelik borudur ve özellikle petrol ve gaz çıkarımının zorlu ortamlarında petrol sahası borusu olarak kullanılmak üzere tasarlanmıştır.Sıkı endüstri standartlarını karşılamak için üretilmiştir, bu boru, petrol ve gaz kuyuları içindeki sıvıların güvenli ve verimli taşınmasını sağlamak için gereklidir.,Her biri farklı aşağı delik koşullarına ve operasyonel gereksinimlere uygun benzersiz mekanik özellikler sunar.

Dikişsiz çelik boru olarak inşa edilen API 5CT Tubing, kaynaklı veya üretilmiş borulara kıyasla üstün dayanıklılık ve dayanıklılık sağlar.petrol sahası operasyonlarında tipik olarak karşılaşılan yüksek basınçlara ve koroziv ortamlara dayanma yeteneğini artırmakBu, güvenilirlik ve uzun ömürlülüğün kritik olduğu petrol sahası boruları için ideal bir seçim haline getirir.Tüplerin sağlam yapısı, kullanım ömrü boyunca en iyi performansı sağlar..

Yüzey işleme, fosfatlama, karalama ve lakerleme bitirme ile mevcut olan API 5CT Tubing'in önemli bir özelliğidir.Bu işlemler korozyon direncini artırmaya ve zorlu ortamlarda borunun ömrünü uzatmaya hizmet ederFosfatlama, boya yapışkanlığını ve korozyon direncini artıran koruyucu bir katman sağlarken, siyahlaştırma pas oluşumunu önlemeye yardımcı olan tek tip bir bitki sunar.Laçlama yüzeyi daha da mühürler, çevresel faktörlere karşı ek koruma sağlar.Bu yüzey işlemleri birlikte borunun, zorlu petrol sahası koşullarında bile bütünlüğünü ve görünümünü korumasını sağlar..

API 5CT Tubing, montaj sırasında güvenli ve güvenilir eklemler sağlayan kaynak bağlantısı için tasarlanmıştır.Kaynak bağlantıları, dayanıklılıkları ve sızıntı geçirmez özellikleri nedeniyle birçok petrol ve gaz uygulamasında tercih edilir, kuyunun bütünlüğünü korumak için hayati önem taşıyan maddeler.Bu bağlantı türü, tarlada montaj işlemini basitleştirir ve borunun çeşitli kuyu konfigürasyonlarına ve derinliklerine uyarlanabilmesini sağlar.

Kalite güvencesi ve denetimi, API 5CT Tubing üretiminde çok önemlidir.Tüp, uluslararası standartlara ve müşteri özelliklerine uygunluğunu doğrulamak için katı bir üçüncü taraf denetimine tabi tutulur.SGS, BV ve DNV dahil olmak üzere tanınmış kurumlar aracılığıyla kapsamlı test ve sertifikasyon sağlanmaktadır.Kimyasal bileşim, boyut doğruluğu ve tüpün genel kalitesi, kullanıcılara ürünün performansına ve güvenliğine güven kazandırıyor.

API 5CT Tubing gibi petrol sahası boruları, petrol ve gaz endüstrisinde vazgeçilmez bir rol oynarken, hidrokarbonların çıkarılmasında ve taşınmasında kritik bir rol oynamaktadır.Yüksek kaliteli malzemelerden oluşuyor., dikişsiz yapı, özel yüzey işlemleri ve sıkı kalite kontrol önlemleri, güvenilir petrol ve gaz boru çözümleri arayan operatörler için tercih edilen bir seçim haline getirir.Kazdırmak için, üretim veya müdahale operasyonları, bu boru, petrol sahasında karşılaşılan en zorlu ortamlarda güvenilirliği ve verimliliği sağlar.

Özetle, API 5CT Tubing, malzeme dayanıklılığı, korozyon direnci ve üretim hassasiyetinin en iyi karışımını sunar.dikişsiz çelik yapısı, koruyucu yüzey tedavileri, kaynak bağlantıları ve kapsamlı üçüncü taraf denetimleri, petrol sahası boru uygulamaları için üst düzey bir ürün olarak öne çıkıyor.Bu boru petrol ve gaz endüstrisinin katı taleplerini karşılamak için tasarlanmıştır, kuyular içindeki sıvıların taşınması için güvenilir ve uzun ömürlü bir çözüm sunarak, böylece dünya çapında güvenli ve verimli petrol ve gaz üretim operasyonlarını desteklemektedir.

Özellikleri:

- Ürün Adı: API 5CT Tubing

- Tip: dikişsiz çelik boru

- Denetim: Üçüncü Taraf Denetimi, Mühendis Test Sertifikası, SGS, BV, DNV

- Bağlantı Tipi: EUE, NUE, STC, LTC, BTC

- İplik Eğimi: 8, 10, 12, 14, 16, 18, 20 İplik

- Yüzey Tedavisi: Fosfatlama, Siyahlama, Laklama

- Borlama boruları, kabuk boruları ve petrol sahası boruları için uygundur

Teknik parametreler:

| Standart |

API Spec 5CT, ISO 11960 |

| Türü |

Dikişsiz çelik boru |

| İpleme Hızı |

8, 10, 12, 14, 16, 18, 20 iplik Inch başına |

| Bağlantı |

Kaynaklama |

| Denetim |

Üçüncü Taraf Denetimi, Mühendislik Deneme Sertifikası, SGS, BV, DNV |

| İp biçimi |

Yuvarlak, destekleyici, özel bıçak |

| Bağlantı Tipi |

EUE, NUE, STC, LTC, BTC |

| Yüzey Tedavisi |

Fosfatlama, Siyahlama, Laklama |

| Malzeme |

K55, N80, L80, P110 |

| Dış çapı |

21.9 - 812.8 mm |

Uygulamalar:

Çin'de gururla üretilen ve ISO 9001 sertifikalı API 5CT Tubing ürünü, petrol ve gaz endüstrisinde gerekli bir bileşendir.Bu ürün çeşitli kabuk boru uygulamaları için idealdir, zorlu ortamlarda dayanıklılık ve güvenilirliği sağlar. En az 1 TON sipariş miktarı ile hem küçük ölçekli hem de büyük ölçekli projeler için uygundur,farklı operasyonel ihtiyaçlar için çok yönlü bir seçim yapar.

API 5CT Tüpler, petrol ve gazın çıkarılmasında ve taşınmasında kritik bir rol oynayan petrol sahası tüpleri ve sondaj tüpleri olarak yaygın olarak kullanılır.Güçlü yapısı kuyuların yapısal bütünlüğünü destekler., sondaj ekipmanlarını etkili bir şekilde koruyan ve kuyunun istikrarını koruyan boruların dış çapı 21.9 mm'den 812.8 mm'e kadar değişir ve çeşitli kuyunun boyutlarına ve derinliklerine uyum sağlar.Bu uyarlanabilirlik, çeşitli sondaj senaryoları için tercih edilen bir seçenek haline getiriyor, sığ kuyulardan derin kuyulara.

Tüp, yuvarlak, destekleyici ve özel konvel de dahil olmak üzere çoklu iplik biçimlerine sahiptir, bu da EUE, NUE, STC, LTC ve BTC gibi çeşitli bağlantı türleriyle uyumluluğunu artırır.Bu bağlantı seçenekleri güvenli ve sızıntı geçirmez eklemleri sağlar, petrol sahası operasyonlarında operasyonel güvenliğin ve verimliliğin korunması için çok önemlidir.kaynak bağlantı yöntemi, boruların yüksek basınç ve sondaj ortamları için tipik olan sert koşullar altında dayanıklılığını daha da güçlendirir..

Paketleme ayrıntıları, güvenli nakliye ve depolanmayı sağlamak için paketleme ve dokuma torbaları içerir.LC ve TT gibi ödeme koşulları alıcılara esneklik sunar, işlemlerin ve tedarik süreçlerinin sorunsuz olmasını kolaylaştırır.

API 5CT Tubing, sondaj operasyonlarının genel performansını artırmak için sondaj ekipmanlarıyla sorunsuz bir şekilde entegre olmak için özel olarak tasarlanmıştır.Yüksek kaliteli üretim standartları ve çok yönlü özellikleri, kabuk boruları için vazgeçilmez hale getirir.Bu tüp ürünü, yeni sondaj projeleri için ya da mevcut kuyularda bakım ve değişim için olsun, en iyi performansı, güvenliğini,ve tarlada uzun ömürlü olmak..

Özellik:

API 5CT Tubing ürünümüz, petrol ve gaz endüstrisindeki özel ihtiyaçlarınızı karşılamak için özel olarak tasarlanmış kapsamlı ürün özelleştirme hizmetleri sunar.Çin'de sıkı bir ISO 9001 sertifikası altında üretildi., kabuk borularımız yüksek kalite ve güvenilirliği talepkâr petrol sahası uygulamaları için sağlar.

En az 1 ton sipariş miktarı, güvenli paketleme ve nakliye sırasında boruyu korumak için dokuma poşetleri de dahil olmak üzere paketleme ayrıntıları ile temin ediyoruz.LC gibi esnek ödeme şartlarını kabul ediyoruz., TT ve diğerleri iş gereksinimlerinize göre.

Tüp, kaynak bağlantısı tipine sahiptir ve API Spec 5CT ve ISO 11960 gibi en yüksek standartlara uymaktadır.Çeşitli petrol sahası boru projelerinde çok yönlü bir uygulamaya izin veren.

API 5CT tüplerimiz 21.9 ila 812.8 mm arasında bir dış çap aralığında gelir ve K55, N80, L80 ve P110 gibi birinci sınıf malzemelerden yapılır.Sert petrol sahası ortamlarında dayanıklılık ve performans sağlamakYağ ve gaz borularına veya özel kabuk borularına ihtiyacınız olsun, ürün özelleştirme hizmetlerimiz operasyonel taleplerinizi verimli ve etkili bir şekilde karşılamak için tasarlanmıştır.

Destek ve Hizmetler:

API 5CT Tubing ürünümüz, en iyi performansı ve müşteri memnuniyetini sağlamak için adanmış kapsamlı bir teknik destek ve hizmet ekibi tarafından desteklenmektedir.Ürün seçimi konusunda uzman rehberlik sağlıyoruz.Hizmetlerimiz detaylı teknik belgeleri, özelleştirilmiş eğitim seanslarını,ve deneyimli mühendislerin sorun giderme yardımEk olarak, boruların tüm endüstri standartlarına uyduğunu ve zorlu koşullarda güvenilir bir şekilde çalıştığını sağlamak için yeryüzünde destek ve denetim hizmetleri sunuyoruz.Projenin başarısını her aşamada desteklemek için kalite ve hizmete olan bağlılığımıza güvenin.

Ambalaj ve Nakliye:

API 5CT Tubing, nakliye ve depolama sırasında maksimum korunmayı sağlamak için dikkatlice paketlenmiştir.Her boru borusu çelik kayışlarla sağlam bir şekilde bağlanır ve boru uçlarının hasar görmesini önlemek için uç kapağı ile korunurSonra paketler nemden ve pastan korunmak için su geçirmez ve korozyona karşı bir malzemeyle sarılır.

Nakliye için boru, nakliye sırasında hareket ve çarpışmayı önlemek için uygun destek ve yastıklarla kamyonlara veya konteynerlere yüklenir.Tüm ambalajlar, ürünün en iyi durumda varış noktasına ulaşmasını sağlamak için uluslararası nakliye standartlarına uymaktadır.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!