Ürün Açıklaması:

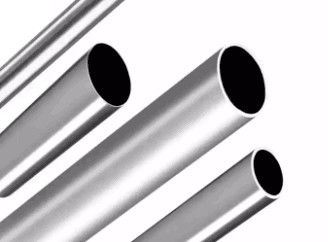

API 5CT Tubing, petrol ve gaz endüstrisindeki sondaj ekipmanlarında kullanılmak üzere özel olarak tasarlanmış yüksek kaliteli bir üründür. API Spec 5CT ve ISO 11960 standartlarının sıkı gerekliliklerine uygun olarak üretilen bu boru, zorlu petrol sahası uygulamalarında olağanüstü performans, dayanıklılık ve güvenlik sağlar. API 5CT Tubing, çeşitli sondaj ve tamamlama operasyonlarında güvenilir hizmet sunan, petrol sahası boruları için endüstri standardı olarak geniş çapta tanınmaktadır.

K55, N80, L80 ve P110 dahil birinci sınıf malzemelerden üretilen API 5CT Boru, farklı operasyonel ihtiyaçları karşılamak üzere tasarlanmış bir dizi mekanik özellik sunar. K55 boru sistemi genel amaçlı uygulamalarda yaygın olarak kullanılır ve iyi bir güç ve dayanıklılık sunar. N80 kalitesi, korozyona karşı daha fazla güç ve direnç sağlayarak onu daha zorlu ortamlara uygun hale getirir. L80 boru sistemi, kötü hizmet koşulları için ideal olan sülfit stres çatlamasına (SSC) karşı yüksek direnç sunar. P110 sınıfı borular, gelişmiş petrol sahası operasyonlarında karşılaşılan aşırı kuyu içi basınçlara ve zorlu ortamlara dayanacak şekilde tasarlanmış en yüksek mukavemetli seçenektir.

API 5CT Boru, 21,9 mm'den etkileyici 812,8 mm'ye kadar geniş bir dış çap yelpazesinde mevcuttur. Bu geniş boyut aralığı, farklı kuyu boyutları ve konfigürasyonlarında çok yönlü uygulamaya olanak tanıyarak çok çeşitli sondaj ekipmanı ve kuyu tasarımlarıyla uyumluluğu garanti eder. İster geleneksel kuyularda ister daha karmaşık sondaj senaryolarında kullanılsın, bu boru sistemi tutarlı performansı ve güvenilirliği korur.

Kalite güvencesi, API 5CT Boru üretim sürecinin kritik bir yönüdür. En yüksek standartları garanti etmek için borular sıkı test ve denetim protokollerinden geçirilir. Bunlar, saygın kuruluşlar tarafından yapılan Üçüncü Taraf Denetimlerini ve malzemenin kimyasal bileşimini ve mekanik özelliklerini doğrulayan kapsamlı Değirmen Testi Sertifikalarını içerir. Ayrıca ürün, SGS, BV (Bureau Veritas) ve DNV (Det Norske Veritas) gibi dünya çapında tanınan denetim kuruluşları tarafından sertifikalandırılmış olup, bu da uluslararası kalite ve güvenlik standartlarına uygunluğunu daha da doğrulamaktadır.

Petrol sahası boruları, hidrokarbonların güvenli ve verimli bir şekilde çıkarılmasında hayati bir rol oynar ve petrol ve gazın rezervuardan yüzeye taşınması için bir kanal görevi görür. API 5CT Boru Sistemi, genellikle petrol sahası operasyonlarında karşılaşılan aşırı basınçlara, sıcaklıklara ve aşındırıcı ortamlara dayanacak şekilde tasarlanmıştır. Sağlam yapısı, arızaları önlemeye ve kuyunun kullanım ömrü boyunca kuyu bütünlüğünü korumaya yardımcı olur.

Özetle API 5CT Boru, malzeme çok yönlülüğü, boyutsal kullanılabilirlik ve sıkı kalite sertifikasyonunun bir kombinasyonunu sunan, petrol ve gaz endüstrisinde vazgeçilmez bir bileşendir. K55, N80, L80 ve P110 gibi kalitelerle çok çeşitli delme zorluklarına hitap ederek optimum performans ve güvenlik sağlar. API Spec 5CT ve ISO 11960'ın katı standartlarını karşılayacak şekilde üretilen ve SGS, BV ve DNV'nin kapsamlı üçüncü taraf denetimleri ve sertifikalarıyla desteklenen bu petrol sahası boru sistemi, sondaj ekipmanlarında güvenilir boru şeklinde çözümler arayan operatörler için güvenilir bir seçimdir. Şirketler, API 5CT Tubing'i seçerek operasyonel verimliliği artırabilir, arıza süresini en aza indirebilir ve uluslararası endüstri standartlarına uygunluğu sağlayabilir.

Özellikler:

- Ürün adı: API 5CT Boru

- Diş Formu: Yuvarlak, Payandalı, Özel Eğimli

- Malzeme: K55, N80, L80, P110

- Bağlantı: Kaynak

- Türü: Dikişsiz Çelik Boru

- Denetim: Üçüncü Taraf Denetimi, Değirmen Test Sertifikası, SGS, BV, DNV

- Petrol Sahası Boruları ve Muhafaza Boruları uygulamaları için idealdir

- Endüstri standartlarını karşılayacak şekilde tasarlanmış yüksek kaliteli Petrol Sahası Boruları

Teknik Parametreler:

| Konu Formu |

Yuvarlak, Payandalı, Özel Pahlı |

| Bağlantı |

Kaynak |

| Konu Aralığı |

8, 10, 12, 14, 16, 18, 20 İnç Başına Konu |

| Standart |

API Spesifikasyonu 5CT, ISO 11960 |

| Makine Tipi |

Sondaj Ekipmanları |

| Yüzey İşlem |

Fosfatlama, Karartma, Vernikleme |

| Tip |

Dikişsiz Çelik Boru |

| Bağlantı Türü |

EUE, NUE, STC, LTC, BTC |

| Dış Çap |

21,9 - 812,8 mm |

| Denetleme |

Üçüncü Taraf Denetimi, Değirmen Test Sertifikası, SGS, BV, DNV |

Uygulamalar:

Çin menşeli ve ISO 9001 sertifikalı API 5CT Boru, özellikle petrol ve gaz endüstrisindeki zorlu uygulamalar için tasarlanmıştır. Bu yüksek kaliteli ürün, Petrol Sahası Boruları ve Muhafaza Boruları olarak yaygın şekilde kullanılmaktadır ve hidrokarbonların çıkarılmasında ve taşınmasında kritik bir rol oynamaktadır. Boru, API Spec 5CT ve ISO 11960'ın sıkı standartlarına uygun olarak üretilmiş olup zorlu kuyu içi koşulları altında güvenilirlik ve dayanıklılık sağlar.

Minimum sipariş miktarı 1 TON olan API 5CT Tubing, nakliye ve depolama sırasında malzemeyi korumak için demetler ve dokuma torbalar halinde dikkatlice paketlenir. Teslimat süresi, petrol sahası projelerinin acil ihtiyaçlarını karşılayacak şekilde 40 gün olacak şekilde verimli bir şekilde yönetilmektedir. LC, TT ve diğerleri gibi ödeme koşulları uluslararası alıcılar için esneklik sağlar.

EUE, NUE, STC, LTC ve BTC gibi çeşitli bağlantı türleriyle tasarlanan bu boru ürünü, farklı kuyu konfigürasyonları için çok yönlü seçenekler sunar. Diş adımı inç başına 8 ila 20 diş arasında değişir; yuvarlak, destekli ve özel eğimli tasarımlardaki diş formları mevcut olup zorlu ortamlarda güvenli ve sızdırmaz bağlantılara olanak tanır.

K55, N80, L80 ve P110 gibi birinci sınıf malzemelerden üretilen API 5CT Boru, mükemmel mekanik özellikler, korozyon direnci ve uzun hizmet ömrü sağlar. Bu malzeme sınıfları çeşitli kuyu içi basınçlara ve sıcaklıklara uygun olup, boruları güvenlik ve performansın çok önemli olduğu Petrol Sahası Boruları ve Muhafaza Boruları uygulamalarında kullanım için ideal hale getirir.

API 5CT Tubing'in tipik uygulama senaryoları arasında petrol ve gaz kuyusu sondajı, tamamlama ve üretim aşamaları yer alır. Rezervuardan yüzey tesislerine petrol ve gaz akışı için güvenilir bir kanal sağlamak amacıyla kara ve denizdeki petrol sahalarında yaygın olarak kullanılır. Ayrıca farklı yeraltı oluşumlarını izole ederek kirlenmeyi önleyen ve kuyu bütünlüğünü sağlayan koruyucu bir bariyer görevi görür.

Özetle, API 5CT Boru, petrol sahası operasyonlarında sağlam performans, uluslararası standartlara uygunluk ve çeşitli bağlantı ve diş açma gereksinimlerine uyarlanabilirlik sunan kritik bir bileşendir. Petrol Sahası Boruları ve Muhafaza Boruları uygulamalarındaki kullanımı, karmaşık ve zorlu petrol sahası koşullarında operasyonel verimlilik ve güvenlik sağlar.

Özelleştirme:

API 5CT Boru ürünümüz, güvenilirlik ve performansı sağlamak için ISO 9001 sertifikasyon standartlarına uygun, Çin'de üretilen yüksek kaliteli bir Petrol Sahası Boru çözümüdür. Minimum sipariş miktarı 1 TON'dan başlayarak, çeşitli proje boyutlarına ve gereksinimlerine uygun ürün özelleştirme hizmetleri sunuyoruz.

API 5CT Boru, API Spec 5CT ve ISO 11960 standartlarının sıkı spesifikasyonlarını karşılamak üzere tasarlanmış, dış çapı 21,9 ile 812,8 mm arasında değişen dikişsiz çelik boru yapısına sahiptir. Çeşitli petrol sahası uygulamalarına uyacak şekilde kaynak bağlantılarıyla yuvarlak, payandalı ve özel eğimli dahil olmak üzere çoklu diş formu seçenekleri sunuyoruz.

Nakliye sırasında Petrol Sahası Borusunu korumak için paketleme, demetler ve dokuma torbalarla dikkatlice taşınır. Teslimat süremiz 40 gün olup, operasyonlarınız için zamanında tedarik sağlar. Ödeme koşulları esnektir ve sorunsuz işlemleri kolaylaştırmak için LC, TT ve diğer yöntemleri içerir.

Operasyonel taleplerinizi karşılayan dayanıklı, uyumlu ve hassas şekilde uyarlanmış Petrol Sahası Boruları için API 5CT Boru özelleştirme hizmetlerimize güvenin.

Destek ve Hizmetler:

API 5CT Boru ürünlerimiz, zorlu endüstri standartlarını karşılayacak ve zorlu petrol ve gaz uygulamalarında güvenilir performans sağlayacak şekilde tasarlanmıştır. Borunun kullanım ömrü boyunca en uygun ürün seçimini, uygulamasını ve bakımını sağlamak için kapsamlı teknik destek sunuyoruz.

Teknik destek, ürün özellikleriyle ilgili yardımı, uyumluluk değerlendirmelerini ve boru bütünlüğünü ve hizmet ömrünü en üst düzeye çıkarmak için kurulum ve taşıma prosedürlerine ilişkin rehberliği içerir.

Hizmetlerimiz, malzeme seçimi, ısıl işlem seçenekleri ve boyutsal özelleştirme de dahil olmak üzere belirli proje gereksinimlerine göre uyarlanmış özelleştirilmiş çözümleri kapsamaktadır.

Ayrıca sorunların hızlı bir şekilde tanımlanmasına ve düzeltilmesine yardımcı olmak, arıza süresini ve operasyonel riskleri en aza indirmek için arıza analizi ve sorun giderme hizmetleri de sağlıyoruz.

Ekibinizin API 5CT Tubing ile ilgili en son endüstri uygulamaları ve ürün yenilikleri hakkında bilgi sahibi olmasına yardımcı olmak için sürekli eğitim ve danışmanlık hizmetleri mevcuttur.

Paketleme ve Nakliye:

API 5CT Tubing, taşıma ve taşıma sırasında maksimum korumayı sağlamak için dikkatli bir şekilde paketlenmiştir. Her boru bağlantısı, hasar ve korozyonu önlemek için koruyucu malzemelerle ayrı ayrı sarılır. Boru daha sonra nakliye boyunca stabiliteyi korumak için güvenli bir şekilde paketlenir ve bağlanır.

Nakliye için API 5CT Tubing, sipariş boyutuna ve varış yeri gerekliliklerine bağlı olarak sağlam paletlere veya özel kasalara yüklenir. Tüm paketler, sorunsuz lojistiği kolaylaştırmak için ürün özellikleri ve taşıma talimatlarıyla açıkça etiketlenmiştir. Paketleme ve nakliye süreçlerimiz, hortumun varış noktasına en iyi durumda ulaşmasını garanti etmek için uluslararası standartlara uygundur.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!